| |

|

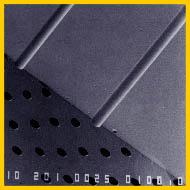

Capillaries

and Capillary Structures

CHI

manufactures structures of collimated holes, also known as

capillary arrays. The concept of large plates of parallel

holes was an important part of the inspiration for the creation

of the company in 1975. Through our glass

drawing and etching processes,

we

produce arrays, disks, plates, and individual capillaries

with a wide range of capillary

diameters, geometries

and plate

sizes, all within certain

tolerances.

Capillaries

and capillary arrays can also be made using drawn tubes. In

general, drawn tube structures and arrays are not quite as

tightly packed and uniform as fused, etched structures; drawn

tubes are not limited by the length

to diameter ratio restrictions inherent in the etching

process, and they result in smoother interior

surfaces than those found in etched capillaries. Both

types of capillary structures have OAR’s

that can be adjusted from less than 1% to nearly 70%. Some

non-confidential applications

of capillary arrays are described herein.

Price

chart for standard Capillary Plates

|

|

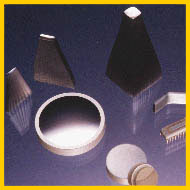

Fiber

Optics

Since

incorporation in 1975, CHI has been producing glass optical

fibers in small and large quantities

for special applications. We have built a wide base of glass

drawing experience over the intervening years with the

production of millions of miles of standard and custom fibers,

in an array of diameters, geometries,

OAR’s, numerical

apertures, and glass types.

We keep a wide variety of glasses, including our patented

terbium-doped scintillating glass, in stock to minimize lead

times and to optimize engineering flexibility.

By

stacking individual fibers into multi-fibers,

we are able to produce many types of fused fiber optics, such

as light guides, multi-fiber image

conduits, Fiber Optic Face Plates,

image remapping devices, and

fiber arrays. We also have the ability to add a layer of EMA

(Extra-Mural Absorbing) glass to the exterior of individual

fibers or between fibers in a fused fiberoptic, to reduce

light leakage and fiber cross-talk.

|

|

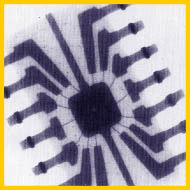

Scintillators

CHI

holds five patents on terbium-activated luminescent glasses.

From these glasses, we manufacture both bulk (non-fiber) and

fiber optic structures that convert non-visible, high-energy

radiation into visible, green light. Scintillating fiber optic

faceplates are commonly used as X-ray conversion screens for

industrial inspection systems. X-rays and other high-energy

radiation enter the scintillating glass and stimulate the

emission of green photons, and those that meet the total internal

reflection angle requirements are then transmitted along the

length of the fiber. Adding a mirror coating to the input

side can roughly double the light output of a scintillating

fiberoptic. The scintillating glass formulation has emission

peaks at 555nm and 565nm, and a decay time of 2ms to 40% value.

Emission

Spectrum and related data

Hybrid Scintillators for X-Ray Imaging Paper from SPIE 1996 (by Clifford Bueno, Richard L. Rairden, and Robert A. Betz)

Comparison of X-Ray Absorption, Light Output, and Afterglow in Glass FOS and Polycrystaline Scintillators

(by Clifford Bueno)

|

About

CHI | Products | Services

| Publications | Contact

CHI | Home

|